what size pole light to compare with 150 watt high pressure sodium light

High pressure sodium vapor (HPS) lights, similar to LPS lights, are a specific type of gas- discharge light (likewise known as a high intensity discharge, HID or arc light). The principal divergence between low and high pressure sodium lights is the operating pressure within the lamp. Every bit indicated by the proper noun, "high" pressure level sodium vapor lights operate at a higher internal force per unit area. The arc tube is made of aluminum oxide and the sodium metallic is combined with several other elements similar mercury which counter-balances the xanthous glow with some white to lite blue emissions. Low pressure level sodium vapor (LPS) lights are a specif ic blazon of gas-discharge light (as well known as a loftier intensity discharge, HID or arc light). The bulb principally contains solid sodium metallic inside a borosilicate drinking glass tube that vaporizes in one case the lamp is turned on. During commencement (while the sodium is still in solid class) the lamp emits a dim cerise/pink glow. Once the metal is vaporized the emissions become the characteristic bright yellow associated with sodium vapor lamps. The spectrum of visible emissions from an LPS light is actually very shut together (589 and 589.six nm, almost monochromatic) resulting in the colors of illuminated objects being nearly duplicate. Both low and loftier force per unit area sodium lights require ignition which is typically provided by a voltage pulse or a third electrode (an boosted metal part) internal to the bulb. Starting is relatively simple with pocket-sized tubes only tin require significant voltage with larger lights. Sodium vapor lighting typically requires a "warm-up" flow in order to evaporate the internal gas into plasma. Additionally, as the light heats up it requires boosted voltage to operate which is counterbalanced by a ballast (a magnetic or electric device designed to provide the lite constant electric current). As sodium vapor lights age, more and more than voltage is required to produce the aforementioned amount of light until eventually the voltage exceeds the fixed resistance provided by the ballast and the calorie-free goes out (fails). The lights become less efficient over fourth dimension because they must use more and more than voltage to produce the same lumen output every bit the low-cal degrades. That said, HPS lights in particular maintain fairly good light output (roughly 80%) at their typical end-of-life (24,000 operating hours). Sodium vapor lighting has been around since the middle of the 20th century (in commercial production since the 1930s) and information technology mostly represents a loftier efficiency way to provide lighting over a vast area. Sodium lights operate in a range where the homo eye is very sensitive and so there is less ability required to attain the same lighting event. For this reason they are very efficient. Additionally, despite their long warm-upwards menses (v-10 minutes), depression pressure sodium lamps will re-ignite immediately in the event of a power intermission. Information technology is specially useful for outdoor lighting where energy efficiency is at a premium (such as with municipalities lighting the streets or other mutual areas like parking lots.) LPS and HPS lights are much more efficient as well as longer lasting than incandescent bulbs, many fluorescent bulbs, and most loftier intensity discharge lamps in full general. It is only recently with the advent of affordable and prevalent LED lighting that they are being consistently surpassed in terms of energy efficiency and lifespan. Amongst the deficiencies in this lighting are the following: Among the small deficiencies in sodium vapor lighting are the following: Common applications for sodium vapor lighting includes street lighting and parking lots also as for tunnel lighting where colour rendering isn't a major issue. Information technology is typically used in outdoor environments for organizations similar schools, large commercial buildings like hospitals, or municipalities managing city lighting on a budget. LED stands for light emitting diode . A diode is an electric device or component with two electrodes (an anode and a cathode) through which electricity flows - characteristically in only one direction (in through the anode and out through the cathode). Diodes are mostly fabricated from semi-conductive materials such as silicon or selenium - solid state substances that conduct electricity in some circumstances and non in others (e.g. at certain voltages, current levels, or calorie-free intensities). When current passes through the semiconductor material the device emits visible light. It is very much the reverse of a photovoltaic cell (a device that converts visible light into electrical electric current). If you're interested in the technical details of how an LED works you can read more about information technology here. There are four major advantages to LED lighting: In improver to the major advantages, LED lights also offer several smaller perks. These include the following: Considering the upside you might recollect that LED lights are a no-brainer. While this is increasingly becoming the case, in that location are still a few tradeoffs that need to be made when you choose LED: In particular, LED lights are relatively expensive. The upward-forepart costs of an LED lighting project are typically greater than about of the alternatives. This is past far the biggest downside that needs to be considered. That said, the price of LEDs are rapidly decreasing and as they continue to be adopted en masse the price will keep to drop. (Don't give up if y ou received an expensive proposal to upgrade to LEDs. Our value technology service tin can aid.) The outset practical apply of LEDs was in circuit boards for computers. Since and so they accept gradually expanded their applications to include traffic lights, lighted signs, and more recently, indoor and outdoor lighting. Much similar fluorescent lights, modern LED lights are a wonderful solution for gymnasiums, warehouses, schools and commercial buildings. They are also adaptable for large public areas (which crave powerful, efficient lights over a big area), road lighting (which offer meaning color advantages over low and high force per unit area sodium lights), and parking lots. We also accept a blog postal service with an interesting accept on the history of street lighting in the United States . The 2 dissimilar technologies are entirely different methods of producing light. Sodium vapor bulbs incorporate metals that are evaporated into inert gas inside the glass casing while LEDs are a solid state engineering science. Both technologies are very efficient. The difference is that sodium vapor lights were the most efficient technology of the 1970s while LEDs are the modern day equivalent. Although sodium vapor lighting beats nearly every other technology in terms of energy efficiency (which is why it was called to illuminate the streets of so many cities), it loses out to LEDs. Both LEDs and sodium vapor lights emit electromagnetic radiations beyond a small portion of the visible light spectrum, withal, LEDs waste matter much less energy producing waste estrus and they also provide an incredibly amend variety of high color rendering index options to the user (thus eliminating the monochromatic black appearance of objects illuminated by LPS and HPS bulbs). Sodium lamps have the worst colour rendering of whatever bulb. They produce a dark yellow glow which is generally a very depression quality light. Additionally, at that place are serious waste material disposal issues with sodium lamps. In particular, they accept been known to start fires in the event that the lamp is cleaved and the sodium metal is exposed. The sodium can catch burn down even in the event that the lamp is cleaved on the ground. For this reason information technology is safest to break sodium lights under water and then to subsequently dispose of the destroyed bulb. Lastly, HPS and LPS lights are monochromatic, so they can mess with your colour vision if you lot await at them for an extended period of fourth dimension. Perchance more than importantly, in the final few years LED efficiency has surpassed that of fifty-fifty LPS and HPS lights and its efficiency improvements are progressing at a much more rapid charge per unit. The largest selling point of LPS and HPS lights is the cheap selling toll, the loftier energy efficiency (depression operating costs), and the relatively long lifespan. LPS and HPS however retain these advantages over most conventional bulbs merely they lose on all iii counts to LEDs. In some areas (e.g. lifespan) they are drastically inferior to LEDs. The extremely low maintenance and replacement costs with LEDs is actually a major cost benefit over the long term. LED lifespan can be greater than 100,000 hours (more than four times that of LPS or HPS). Having to buy one bulb versus iii or four bulbs over the form of time is a significant selling bespeak for LEDs. The bottom line is that having lost their traditional advantage of beingness the most energy efficient bulb on the market, there's very little reason to use a sodium vapor light when LED lighting is available. LEDs are available in a broad range of color temperatures that generally span from 2200K-6000K (ranging from "warm" yellow to calorie-free or "absurd" blue). Low and High Pressure Sodium lights are well-known for their warm yellow glow (CCT values around 2200K). Although Loftier Pressure Sodium lamps emit visible light across a slightly more wide spectrum than Depression Pressure Sodium lamps, they are still very express. The downside is that there are very few options exterior the narrow range to choose from. In other words, if you're not looking for a warm deep xanthous light, you're going to have to use something as well Low or Loftier Pressure Sodium to reach information technology. WINNER: LEDs CRI for LED is highly dependent on the detail lite in question. That said, a very wide spectrum of CRI values is bachelor ranging generally from 65-95. Depression Force per unit area Sodium lamps are notorious for having the worst CRI values on the market. Typically they fall effectually 25 on a scale of 100 where 100 is the all-time possible. LPS lamps emit a monochromatic xanthous lite which very much inhibits color vision at dark. Color rendering for High Pressure Sodium lights is slightly improved (HPS lights emit a yellowish to white lite) only it is still much worse than other types of lamps. WINNER: LEDs LEDs are an ideal light for purposely turning on and off because they answer rather instantaneously (there is no warm upwards or cool downward period). They produce steady calorie-free without flicker. Loftier force per unit area sodium bulbs may flicker and/or cycle on and off as the bulb reaches the cease of its useful life. Low Pressure Sodium lamps will not cycle at the finish of life but rather will simply fail to strike (plough on) and/or will stay in the warm-up phase indicated by a dim reddish to pinkish glow. Both Depression and High Pressure Sodium lights exhibit a curt delay when turning on because they need to be ignited earlier they operate at steady land. Problems with the starter and/or improper matching of a starter and an HPS lamp may cause cycling fifty-fifty though the starter is otherwise working properly as the lamp is continually trying to light itself. WINNER: LEDs LEDs are very piece of cake to dim and options are available to use anywhere from 100% of the light to 0.5%. LED dimming functions by either lowering the frontward electric current or modulating the pulse duration. HID lights can be manually dimmed through the use of different electric or magnetic ballast simply the process changes the voltage input to the light and can consequently alter the lite characteristics. In some cases (particularly with older HID bulbs) dimming can crusade the light to prematurely expire. Continuous dimming typically alters the light output from 100% to xxx% for Loftier Pressure Sodium lamps. WINNER: LEDs LEDs emit light for 180 degrees. This is typically an reward because low-cal is usually desired over a target area (rather than all 360 degrees around the seedling). You lot can read more about the impact of directional lighting by learning about a measurement called "useful lumens" or "system efficiency." All Loftier Intensity Discharge lights (of which HPS and LPS are examples) emit low-cal omnidirectionally. This ways they emit low-cal for 360 degrees, requiring fixture housings or reflectors to direct a big portion of the emissions to the desired target area. WINNER: LEDs LEDs are very efficient relative to every lighting blazon on the market. Typical source efficiency ranges 37 and 120 lumens/watt. Where LEDs really polish, withal, is in their organization efficiency (the corporeality of light that actually reaches the target area after all losses are accounted for). Virtually values for LED organization efficiency fall above 50 lumens/watt. Depression and High Pressure Sodium lights are the only light whose source efficiency compares to LEDs (values range between 50 and 160 lumens/watt for LPS and slightly less for HPS). They lose out to LEDs in many cases because their system efficiency is ofttimes much lower due to losses associated with omnidirectional light output and the need to redirect it to a desired area. WINNER: - LED efficiency drops as electric current increases. Heat output also increases with additional current which decreases the lifetime of the device. The overall performance drop is relatively low over time with around 80% output being normal near the end of life. High Pressure Sodium lights maintain their brilliance fairly well with ninety% however available halfway through their lifespan (around 12,000 hours). HPS bulbs typically emit 80% of their original rated output at the end of life (around 24,000 hours). WINNER: - LEDs produce a very narrow spectrum of visible light without the losses to irrelevant radiation types (IR, UV) or heat associated with conventional lighting, significant that nearly of the energy consumed past the light source is converted directly to visible light. Low and High Pressure sodium lights produce a very narrow spectrum of low-cal (specially LPS lights). For this reason LPS lights are actually desirable as they minimize electromagnetic interference most facilities conducting astronomical ascertainment. WINNER: LEDs LED - None HPS - None WINNER: - LEDs emit very piddling forward heat. The merely existent potential downside to this is when LEDs are used for outdoor lighting in wintery conditions. Snowfall falling on traditional lights like HID will cook when it comes into contact with the low-cal. This is usually overcome with LEDs past covering the light with a visor or facing the light down towards the basis. Depression and High Pressure Sodium lights emit heat that is absorbed by the ballast and/or lost to the environs. Roughly 15% of the emissions are lost due to energy dissipation and heat losses. In some circumstances estrus emissions could be benign, even so, it is a generally a bad thing to emit heat as it represents an free energy inefficiency. The ultimate purpose of the device is to emit calorie-free, non heat. WINNER: LEDs LEDs neglect by dimming gradually over time. Because LED lights typically operate with multiple light emitters in a single luminaire the loss of 1 or 2 diodes does not mean failure of the entire luminaire.. Low and High Force per unit area Sodium lights tin can fail in a number of dissimilar ways. Generally they showroom an end-of-life phenomenon known as cycling where the lamp goes on and off without human input prior to eventually failing entirely. WINNER: LEDs Foot candle is a mensurate that describes the amount of light reaching a specified surface area as opposed to the total corporeality of light coming from a source (luminous flux). LEDs are very efficient relative to every lighting type on the market. Typical source efficiency ranges 37 and 120 lumens/watt. Where LEDs actually shine, nevertheless, is in their system efficiency (the amount of light that actually reaches the target area after all losses are accounted for). Most values for LED arrangement efficiency autumn above 50 lumens/watt. HIDs are very efficient compared to CFL and incandescent lights (120 lumens/watt source efficiency). They lose out to LEDs principally because their system efficiency is much lower (<30 lumens/watt) due to all of the losses associated with omnidirectional low-cal output and the demand to redirect information technology to a desired area. Past far the most efficient HID variant is the Low Pressure Sodium lamp whose source efficiency tin can range from 60-190 lumens/watt. WINNER: F oot Candle ratings are very application specific and vary instance by case so it is difficult to say if LPS/HPS or LED would be better performing without the specifics of the particular situation. LEDs concluding longer than whatever calorie-free source commercially bachelor on the market. Lifespans are variable but typical values range from 25,000 hours to 200,000 hours or more earlier a lamp or fixture requires replacement. High Pressure Sodium lights accept excellent lifespan as well (although non as good as LED) which is why they take traditionally been used for outdoor street lighting in municipalities where free energy efficiency is at a premium. Typical lifespan values for an HPS bulb are around 24,000 hours. According to American Electrical Lighting, "HPS lamps all the same generate 90% of their initial light output at the midpoint of their life span. Lumen maintenance at the end of life still is fantabulous at around lxxx%." LPS lights terminal slightly shorter periods of time (typically declining effectually 18,000 hours of operation). WINNER: LEDs LED lighting has relatively high initial costs and low lifetime costs. The technology pays the investor dorsum over time (the payback period). The major payback comes primarily from reduced maintenance costs over time (dependent on labor costs) and secondarily from energy efficiency improvements (dependent on electricity costs). Low and High Pressure Sodium lights are very cheap to purchase also as fairly cheap to maintain. That said, although LPS and HPS bulbs have a long lifespan relative to most competitors, they still autumn brusk of LEDs. LPS or HPS lights will notwithstanding probable demand to be purchased several times and the associated labor costs will need to be paid in social club to attain the equivalent lifespan of a unmarried LED light. WINNER: LEDs LED has virtually nada maintenance costs and the frequency with which bulbs have to exist changed out is by far the best on the market. Depression and High Force per unit area Sodium bulbs are long lasting but volition still crave replacement several times in add-on to the labor cost to monitor and supervene upon aging or expired components all inside the lifespan of a unmarried LED. WINNER: LEDs LED light costs are high only variable depending on the specifications. The typical 100W-equivalent LED lite costs somewhere between $10 and $xx. Depression and High Pressure Sodium costs vary depending on the specific type of light. Generally they are inexpensive compared to LEDs ($v-$10 for a 100W incandescent-equivalent LPS or HPS seedling). WINNER: Low & Loftier Pressure Sodium LEDs are solid state lights (SSLs) that are difficult to impairment with physical shocks. Low and High Pressure Sodium bulbs are frail relative to LEDs. This is especially true of those bulbs in linear tubes. Similar nearly legacy lamps HPS and LPS lamps operate by using a drinking glass bulb. WINNER: LEDs LEDs can be extremely small (less than 2mm in some cases) and they can be scaled to a much larger size. All in all this makes the applications in which LEDs can exist used extremely diverse. Depression and High Pressure Sodium Lamps come in all shapes and sizes but are typically used for outdoor applications where size isn't a major factor. Nevertheless, they typically aren't produced below roughly a centimeter in width and and then they do not compare to the small size and robust build of a solid state calorie-free like LED. WINNER: LEDs LEDs: Minus 40 Degrees Celsius (and they will turn on instantaneously). Depression and High Force per unit area Sodium: -40 Degrees Celsius. WINNER: LEDs LEDs: 100 Degrees Celsius. LEDs are fine for all normal operating temperatures both indoors and outdoors. They do, however, show degraded performance at significantly high temperatures and they require significant oestrus sinking, especially when in proximity to other sensitive components. Low and High Pressure Sodium: We couldn't observe any objective information on fluorescent seedling performance in high temperature situations. If yous have whatever information please contact united states of america. WINNER: - LEDs have most no warm-upwards time. They reach maximum effulgence near instantaneously. Depression and Loftier Pressure Sodium lights require a warm-upwardly time that varies depending on the light. Information technology tin take up to 10 minutes to get the LPS or HPS lamp up to its normal operating temperature. WINNER: LEDs LEDs: Oftentimes 5-10 Years Low and Loftier Pressure Sodium: Typically 1-four Years WINNER: LEDs -2.png?width=204&name=Add%20a%20heading%20(4)-2.png) Ever wonder what's improve: loftier pressure level sodium lights (and the related depression force per unit area sodium lights) or light emitting diodes (LEDs)? Well here'south a head-to-head comparison of the 2 followed past an in-depth discussion of each engineering in turn.

Ever wonder what's improve: loftier pressure level sodium lights (and the related depression force per unit area sodium lights) or light emitting diodes (LEDs)? Well here'south a head-to-head comparison of the 2 followed past an in-depth discussion of each engineering in turn. High Pressure Sodium

What is a High Force per unit area Sodium Low-cal?

Depression Pressure level Sodium

What is a Low Pressure Sodium Light?

Commonalities Between LPS & HPS Lights:

What's the Upside to Low (LPS) and Loftier Pressure (HPS) Sodium Lights?

What are the Major Deficiencies in Low (LPS) and Loftier Pressure (HPS) Sodium Lights?

What are the Pocket-sized Deficiencies in Low (LPS) and Loftier Pressure (HPS) Sodium Lights?

Where are Depression and High Pressure Sodium Lights Commonly Used?

LED Lighting:

What is a Low-cal Emitting Diode (LED)?

What'southward the Major Upside to LED Lights?

What are Modest Upsides to LED Lights?

What's the Downside to LED Lights?

Where is LED Commonly Used?

Qualitative Comparison Between LED & LPS/HPS

What'south the Difference Between Sodium Vapor and LED Lights?

Why LEDs Put Sodium Vapor Lights Out of Business?

Why LEDs Put Sodium Vapor Lights Out of Business? LED vs HPS & LPS

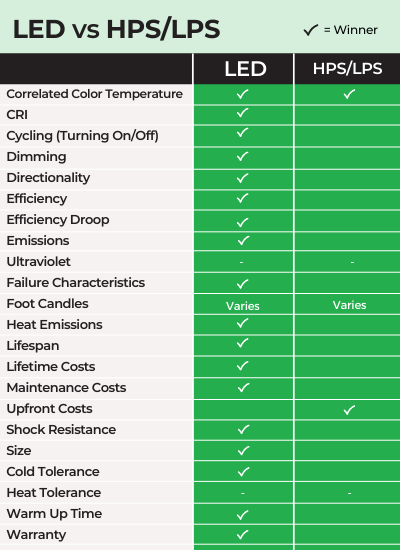

Calorie-free Emitting Diode (LED) vs High pressure Sodium/Low Pressure Sodium Comparison

Correlated Color Temperature (Read more than Here)

CRI

Cycling (Turning On/Off)

Dimming

Directionality

Efficiency

Efficiency Droop

Viable Light Emissions

Infrared & Ultraviolet

Heat Emissions

Failure Characteristics

Foot Candles (Read more than Here)

Lifespan

Lifetime Costs

Maintenance Costs

Upfront Costs

Daze Resistance

Size

Common cold Tolerance

Heat Tolerance

Warm-Upward Time

Warranty

sharlandhositany1960.blogspot.com

Source: https://www.stouchlighting.com/blog/led-vs-hps-lps-high-and-low-pressure-sodium